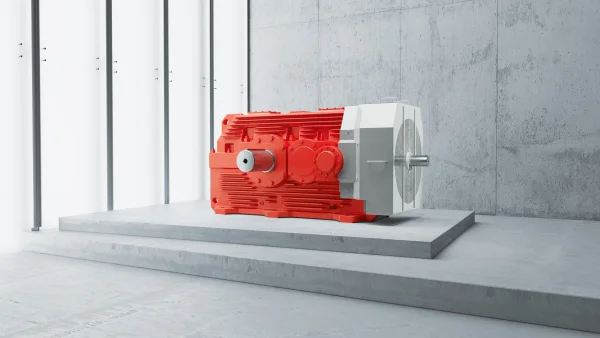

With 23 finely graduated sizes, the helical and bevel-helical gear units of the X..e series cover the torque range from 6.8 to 475 kNm. The extensive modular program and the large number of predefined additional equipment and options offer a high degree of flexibility for adaptation to the application situation. Regardless of whether you are a plant manufacturer or operator - the X..e series offers the right solution for every requirement.

One standard product – numerous possibilities

For operators or original equipment manufacturers of machines and plants, it is crucial that the drives used there are robust, reliable and easy to maintain. The industrial gear units of the X..e series efficiently meet these requirements.

The intelligent, universal gear unit concept impresses with its fine size graduation, high installation variability and the large number of additional modular features and options such as motor adapters, backstop, various sealing and shaft systems, and many more. The wide ratio range of 6.3 - 450 and the robust design make the All-Rounder the right choice in many industries and applications. Whether crane, conveyor belt or mixer - with the X..e series and the industry know-how of SEW-EURODRIVE, you are opting for maximum availability and a reliable partner. And if our modular system does not have the right solution for you, we will customize our gear units for you.

The modular Generation X.e system – benefits for you

This is what makes Generation X.e unique:

Our decades of experience in the construction of large gear units have prompted us to selectively revise the X series. Find out below which innovations make the X.e generation so unique and how the intelligent combination of the implemented measures and the calculation by networked software tools enables you to obtain an exactly fitting gear unit.

Generation X.e – efficient. experienced. excellent

Features

Properties and features of the X..e series industrial gear units

- Independent industrial gear unit platform with 23 sizes

- Helical gear units and bevel-helical gear units

- Single-piece and split gear unit housing

- Invertible gear unit housing

- Universal mounting positions

- Distinctive modular technology

- Diverse predefined optional equipment and options

- Customer-specific adaptations possible

Technical data

| Gear unit design | Stages | Gear ratio i | Nominal torque MN2 kNm |

|---|---|---|---|

| Helical gear unit X.F.100e – X.F.320e |

2 to 4 stages | 6.3 – 450 | 6.8 – 475 |

| Bevel-helical gear unit X.K.100e – X.K.320e |

2 to 4 stages | 6.3 – 450 | 6.8 – 475 |

| Bevel-helical gear unit X.T.100e – X.T.250e |

3 and 4 stages | 12.5 – 450 | 6.8 – 175 |

Application-specific industrial gear units

Applications

Applications

Our helical gear units / bevel-helical gear units are used whenever a high torque is required on a reliable basis from a standard product – in applications from materials handling and crane technology to mixers, crushers and much more besides.

- In mining

- In the cement industry

- In port logistics

The modular Generation X.e system – benefits for you

- SEW GearOil

- Boosts gear unit performance

- Reduces rolling and sliding friction

- Improves efficiency and wear resistance

- Eliminates the need for an initial oil change after 500 hours of operation

- Delivery times

- Short delivery times, even in the case of customized adaptations

- Replacement parts required during servicing can also be supplied quickly

- Global availability

- With four production plants and 13 assembly plants across the globe, standardized industrial gear units can be supplied worldwide impressively fast

- Additional service centers can also provide all kinds of service operations at short notice

- Detailed calculation

- Thanks to a networked calculation landscape, each and every drive is simulated in the software, with calculations based on specific drive data requirements.

- Collaboration with research institutes means the latest calculation models can be used on series products.

- Condition monitoring

- The DriveRadar® IoT Suite monitors parameters such as vibration and temperature on the drive to pre-empt damage to bearings or gearing and temperature-related issues.

- Preventive damage detection with notification option

What does a networked calculation landscape mean for you?

The new networked calculation landscape provides the perfect support for the selective configuration of your gear unit. Our industry experts assist you during this process and can now take the highly specific operating conditions of your application into account.

They are able to do so because the new Generation X.e has been enhanced based specifically on the industry and application experience of both our experts and our customers from the mining, cement and port logistics industries. You, too, can systematically work your way toward ideal and highly efficient operating processes with our intelligent drive solution.

Want to avoid an initial oil change after 500 hours of operation? With our X.. series industrial gear units, you can save yourself the time and expense this involves.

We have established a closely monitored running-in and cleaning process during production. In conjunction with our SEW GearOil lubricants and their unique additives, this means we can provide you with a drive package tailored to your application that will not require an early oil change.

More information about SEW GearOil.

We're happy to help.

If you have any further questions about our Generation X.e, simply complete the form below and send us a message.