You want to bridge lengthy tracks without long conveyor belts and as flexibly as possible? Then you won't get by without mobile materials handling technology. MOVITRANS® is the ideal power supply system for your needs – contactless, silent and wear-free. No space for a control cabinet? With the new decentralized MOVITRANS® you save space and time.

Reliable contactless power supply with MOVITRANS® – now also available without control cabinet

In many production facilities, machines and systems have to be connected over lengthy distances. In the past, expensive and high-maintenance conveyor belts or vehicles requiring a human driver were needed for this task. Nowadays, mobile transport systems easily bridge such distances.

If storage material and goods have to be transported over these long distances both as quickly as possible and clean at the same time, our MOVITRANS® is the perfect energy supply system for automated guided vehicles. This also applies to contamination-sensitive areas where contamination caused by energy transfer has to be avoided.

The solution: With MOVITRANS®, the socket is basically on board. The energy transfer is contactless via an air gap which makes the electromagnetic connection entirely maintenance-free and wear-free. This contactless energy supply enables high speeds of more than 10 m/s.

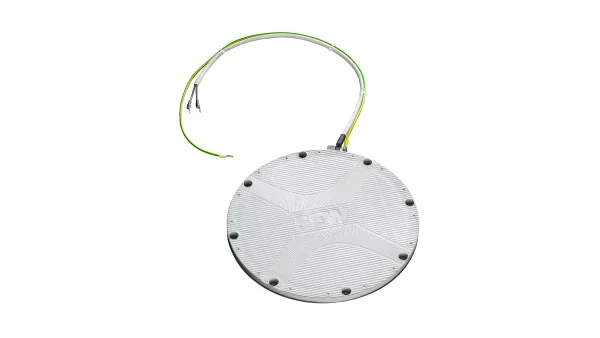

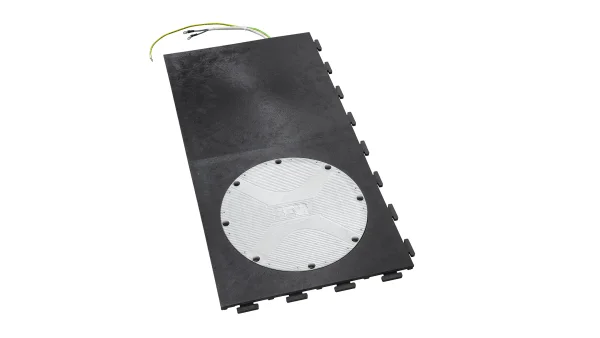

It operates on the principle of inductive energy transfer. Electrical energy is transferred without contact from a fixed conductor or in a stationary manner from a breakpoint via a field plate (charging plate) to one or more mobile consumers. Time-consuming, cumbersome cable carrier and conductor rail systems have become a thing of the past

Get in touch with us

- Our experts know your industry and your requirements

- Our global network ensures we are close wherever and whenever you need us

- We have the expertise and tools to provide optimum advice and support

All in all, the MOVITRANS® decentralized contactless energy transfer system is your ideal choice if you want to keep your costs low and boost your productivity:

- Reduce installation and startup times due to easy handling and the unnecessity of control cabinet installations

- Considerably reduce your investment costs since you can reuse most parts of your existing components if your factory and the system design are changing. And there is no need for new investments.

- Save costs due to the high energy efficiency: The combination of the latest component technologies and short power distribution distances for line or selective charging ensure highly efficient plant operation

- Sustainably minimize your maintenance efforts as MOVITRANS® increases the plant availability.

Last but not least, using our MOVITOOLS® MotionStudio engineering software makes startup and operation of the decentralized and contactless MOVITRANS® technology extremely simple.

Your benefits

-

Easier configuration

With its individual system components, MOVITRANS® can be easily adapted to suit changing system tasks and modifications -

Reduced operating costs

MOVITRANS® is easy to handle, increases the system availability and considerably reduces the maintenance efforts

System features

MOVITRANS® comprises both stationary and mobile system components. These can be integrated into existing automation systems quickly and easily:

- For routing the line cable in the floor, the flat pick-up is used.

- The air gap between the line cable and the pick-up can be up to 20 mm. This enables high transmission power even in situations where the pick-up does not always occur at a constant distance above the line cable.

You do not need a control cabinet

Energy is supplied dynamically during travel via lines routed in the floor

Energy is supplied in a stationary manner at a breakpoint via a field plate installed in the floor (selective charging)

Key

-

1TES decentralized supply unit

-

2

-

3Line cable via TLS medium-frequency cable

-

4

-

5

-

6TFS field plate

Tobias Nittel, product manager for decentralized drive technology at SEW‑EURODRIVE:

"The MOVI-C® modular automation system gives customers the option to implement their application both with inverters in a control cabinet and with drive electronics that are either located close to the motor or integrated into it. What's more, they can do so without noticing any differences in terms of project planning, handling and performance. An essential part of the platform is the digital motor integration. This supports automatic drive train startup and also ensures that various sensor signals can be transmitted from the motor to the electronics without requiring any additional installation work."